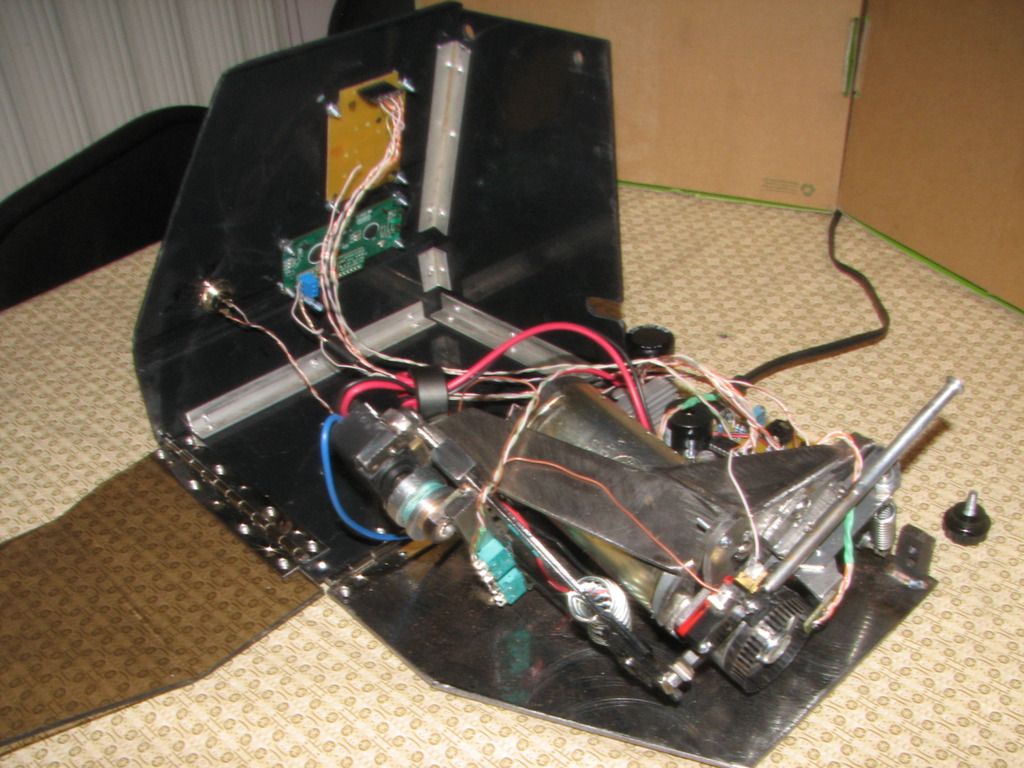

Gattling gun LoL

How many different wire colours or discrete wire types in typical use?

For a future time of course - I was thinking that if you had a sliding rack with feed tubes and a spring retainer, so that only the selected tube at at the feed station was 'unsprung' (a cam at the feed point) then all the wires could be loaded into the appropriate tubes and the rack moved left to right to present the correct one.

Sorry if I caused any offence with my comment early in the thread. It seems that you have it pretty much cracked.

With a wire selector, you could automatically present the cutting list for a complete harness - One harness at a time of course Not something to get wrong though as it could waste a lot of wire. Gosh, this scope creep is infectious.

Not something to get wrong though as it could waste a lot of wire. Gosh, this scope creep is infectious.

Good luck with the project. it sounds interesting and a lot of fun to have it working as you envisaged.

How many different wire colours or discrete wire types in typical use?

For a future time of course - I was thinking that if you had a sliding rack with feed tubes and a spring retainer, so that only the selected tube at at the feed station was 'unsprung' (a cam at the feed point) then all the wires could be loaded into the appropriate tubes and the rack moved left to right to present the correct one.

Sorry if I caused any offence with my comment early in the thread. It seems that you have it pretty much cracked.

With a wire selector, you could automatically present the cutting list for a complete harness - One harness at a time of course

Good luck with the project. it sounds interesting and a lot of fun to have it working as you envisaged.