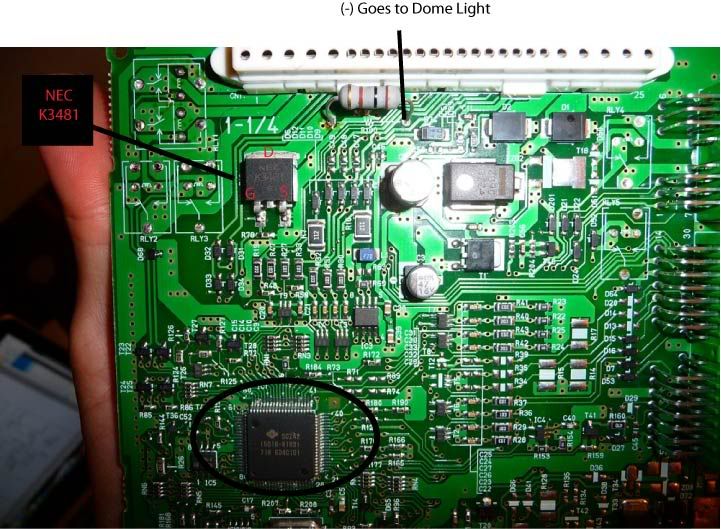

My car has factory theater dimming that fade/on fade/off as you open and close the doors.

The factory system is designed around incandescent bulbs which I have replaced with LEDS and consequently I have lost some of the effect.

The fade/on is gone, the LEDs turn on full bright immediately and the fade/off is rather quick and flicker toward the end (smoothed this out with a cap) I believe the stock system uses PWM but at a frequency not suited for LEDs which causes the flicker toward the end.

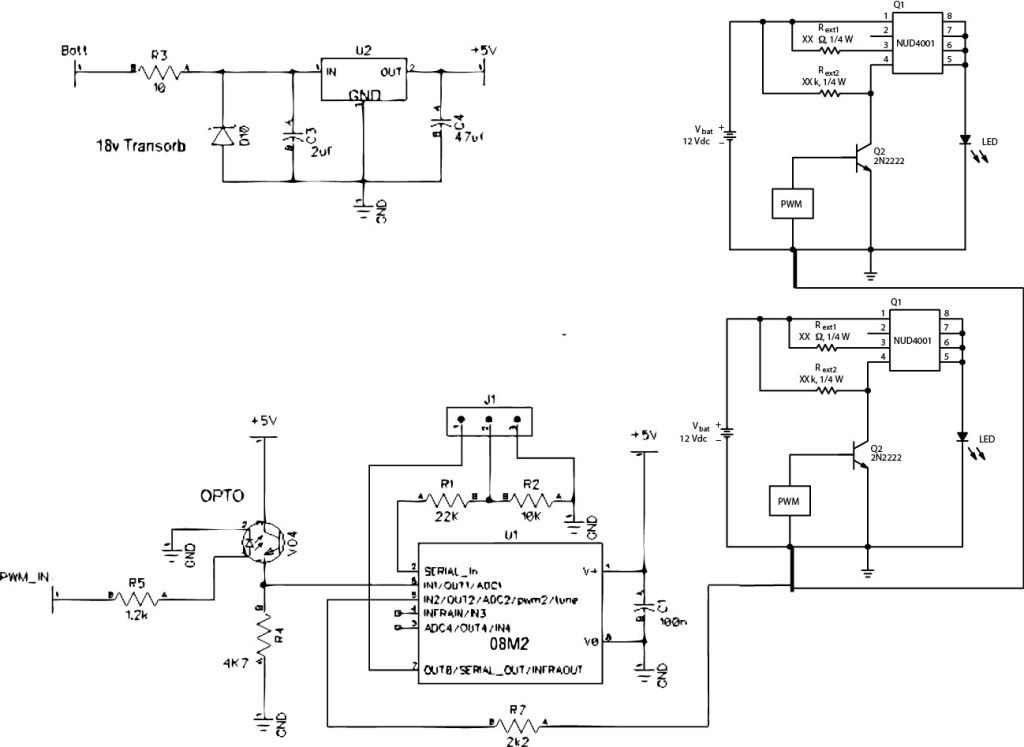

I was thinking about the possibility of using the PICAXE and use the inputs from the OEM system to trigger the PIC and control the fade/on fade/off better.

The LEDs will use a constant current driver with PWM input capabilities. Can I program the PIC to output a 5 seconds fade/up PWM to full brightness and a 5 seconds fade/out triggered by the existing signal from the car?

The factory system is designed around incandescent bulbs which I have replaced with LEDS and consequently I have lost some of the effect.

The fade/on is gone, the LEDs turn on full bright immediately and the fade/off is rather quick and flicker toward the end (smoothed this out with a cap) I believe the stock system uses PWM but at a frequency not suited for LEDs which causes the flicker toward the end.

I was thinking about the possibility of using the PICAXE and use the inputs from the OEM system to trigger the PIC and control the fade/on fade/off better.

The LEDs will use a constant current driver with PWM input capabilities. Can I program the PIC to output a 5 seconds fade/up PWM to full brightness and a 5 seconds fade/out triggered by the existing signal from the car?