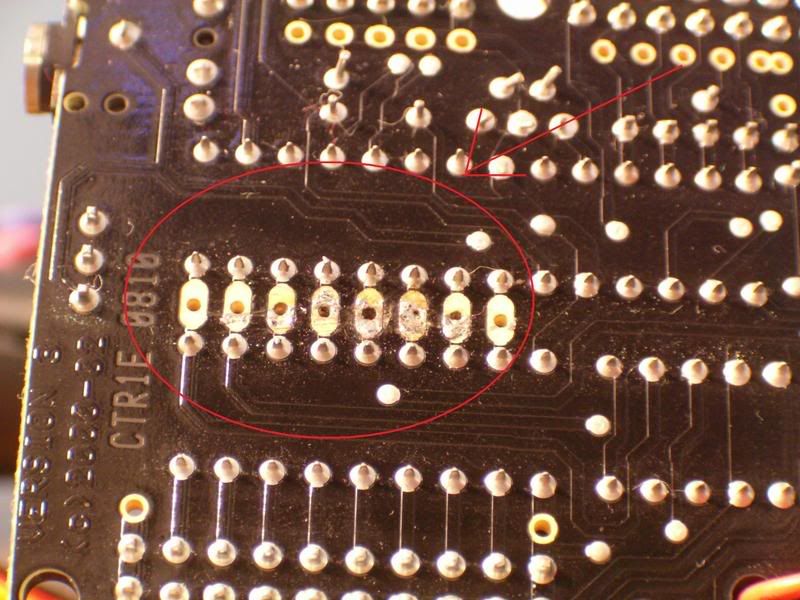

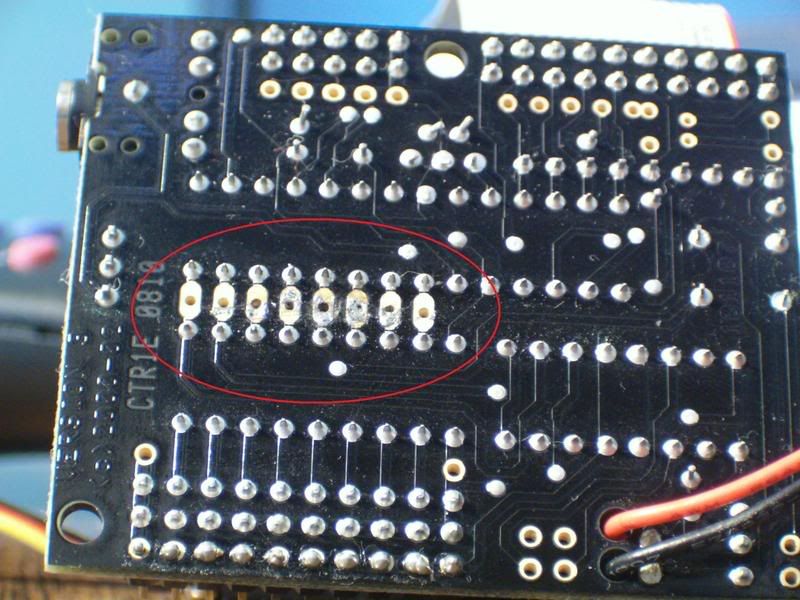

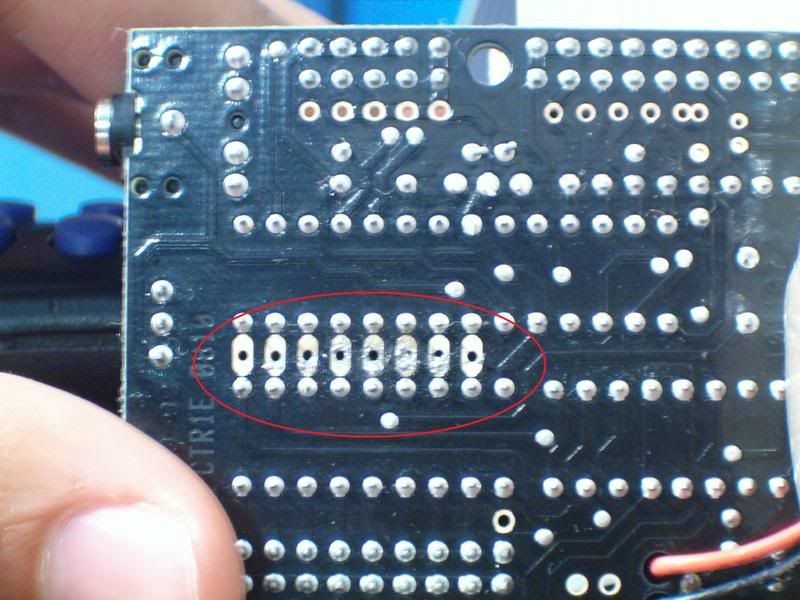

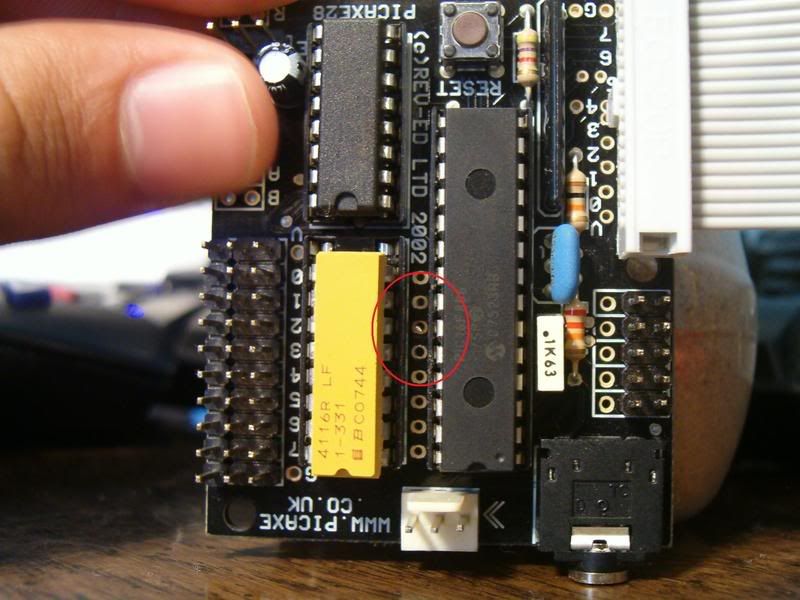

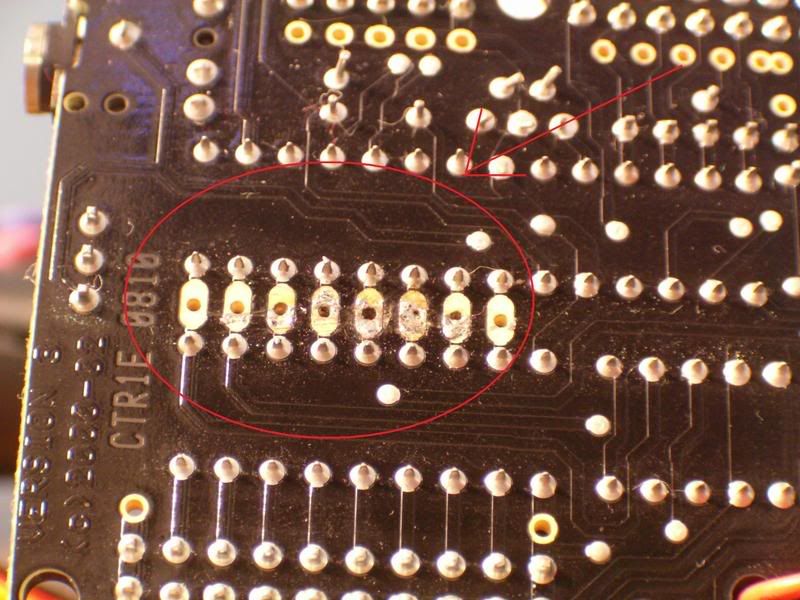

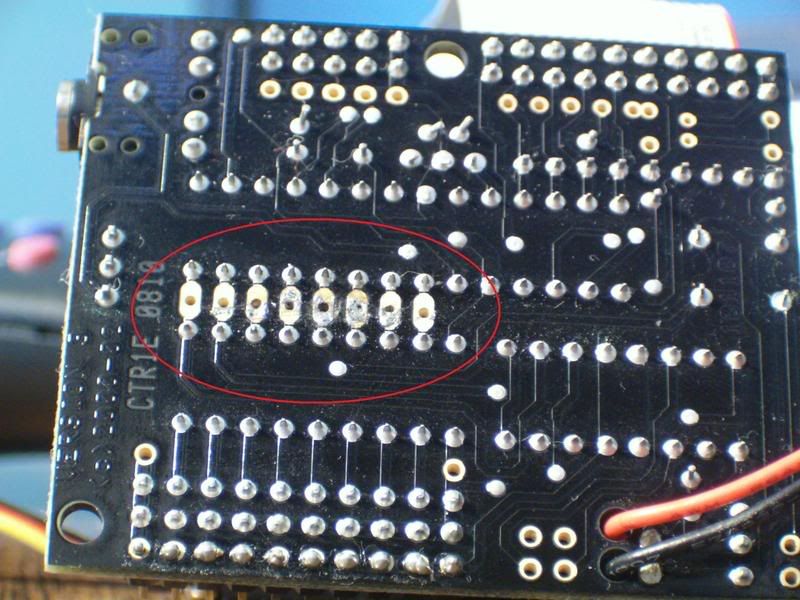

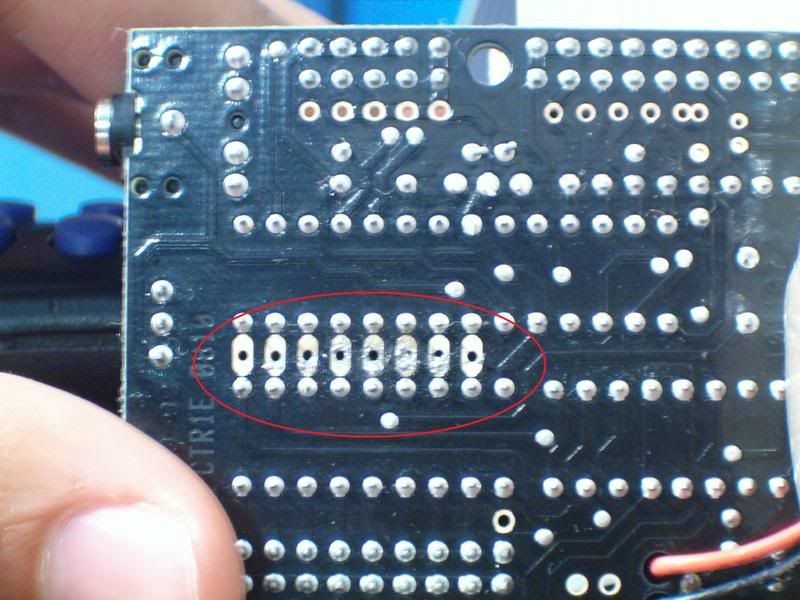

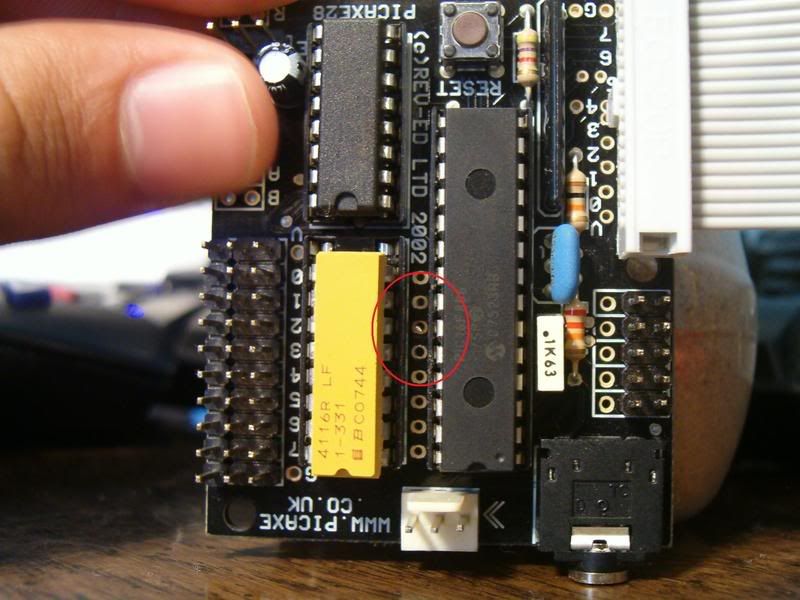

OK, at first I tried using the ribbon cable and it got annoying because I wasnt certain which port would be for which wire, and now I am facing even more difficulties. I attempted to solder a wire to the actual board of the Picaxe, was I supposed to? Or use a pin, now I have excess solder that I think might mess up the connecting, because, as you can see from one of my pictures, its an annoying glob. I have already tried a Vacuum Desoldering Tool, Desoldering Braid, and a Solder Pump So I conclude with two questions:

1. How do I get rid of some of that solder?

2. What is a more practical way to connecting the Sonar to the Microcontroller?

1. How do I get rid of some of that solder?

2. What is a more practical way to connecting the Sonar to the Microcontroller?