joe paul

Senior Member

Hi Folks,

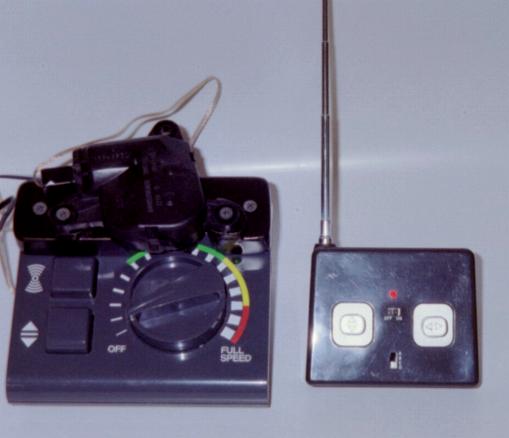

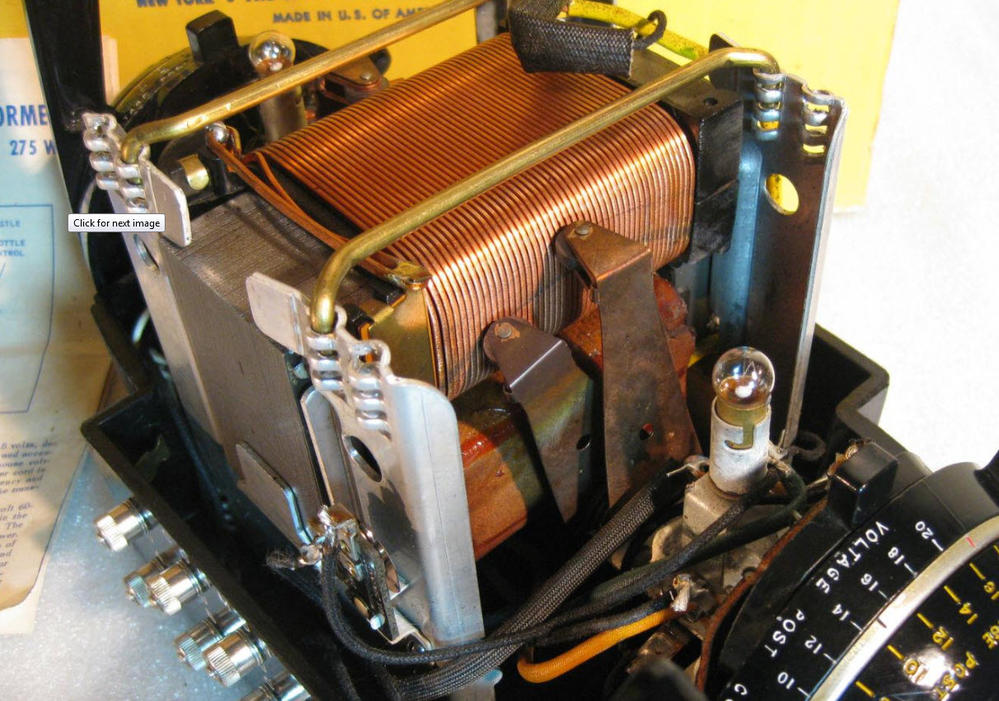

It is rather simple to do PWM for DC, but is there a circuit and similarly easy way to deliver variable AC?

For example, I would like vary the AC from approximately 5 to 18 volts (for AC toy train control) with the 18M2 chip.

Thanks!

Take care, Joe

P.S -- I don't have an oscilloscope, so I wouldn't be able to troubleshoot the circuit. J.

It is rather simple to do PWM for DC, but is there a circuit and similarly easy way to deliver variable AC?

For example, I would like vary the AC from approximately 5 to 18 volts (for AC toy train control) with the 18M2 chip.

Thanks!

Take care, Joe

P.S -- I don't have an oscilloscope, so I wouldn't be able to troubleshoot the circuit. J.